——HBP's Comprehensive Gas Processing Project in Kazakhstan has been honored with the Excellent Engineering Survey and Design Award in the Chinese Petroleum and Chemical Industry. Furthermore, the EPC Project in Chad and the Gas Processing Project in Kazakhstan have received recognition in the Excellent Engineering Survey and Design Awards of Hunan Province.

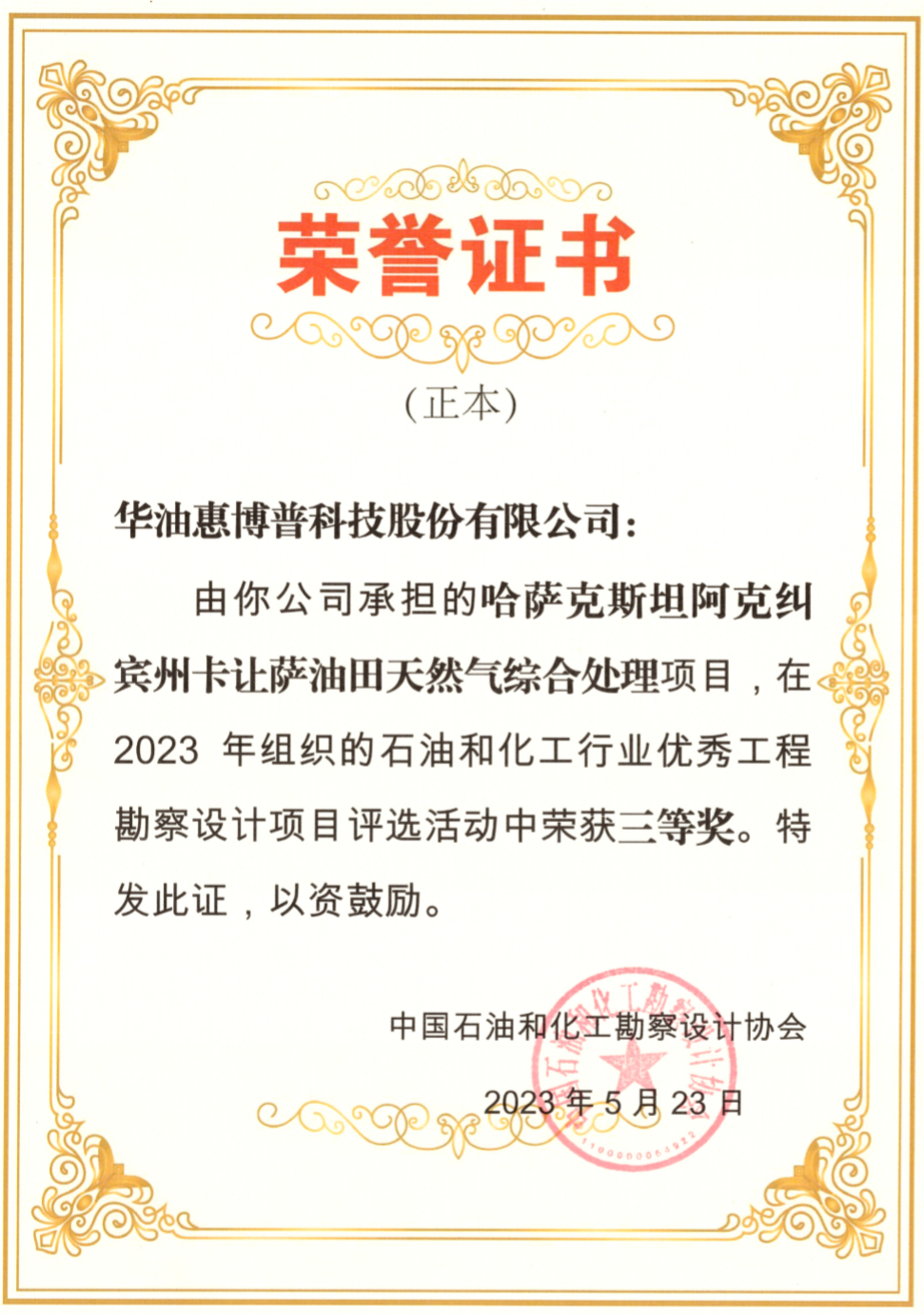

In June 2023, the Petroleum and Chemical Industry Excellent Engineering Survey and Design Awards, organized by the China Petroleum and Chemical Industry Survey and Design Association, concluded. China Oil HBP Science & Technology Co., Ltd. (referred to as "HBP group") was honored with the third prize in the 2023 Petroleum and Chemical Industry Excellent Engineering Survey and Design Project for its comprehensive gas processing project in the Karachaganak Oilfield, Atyrau Region, Kazakhstan.

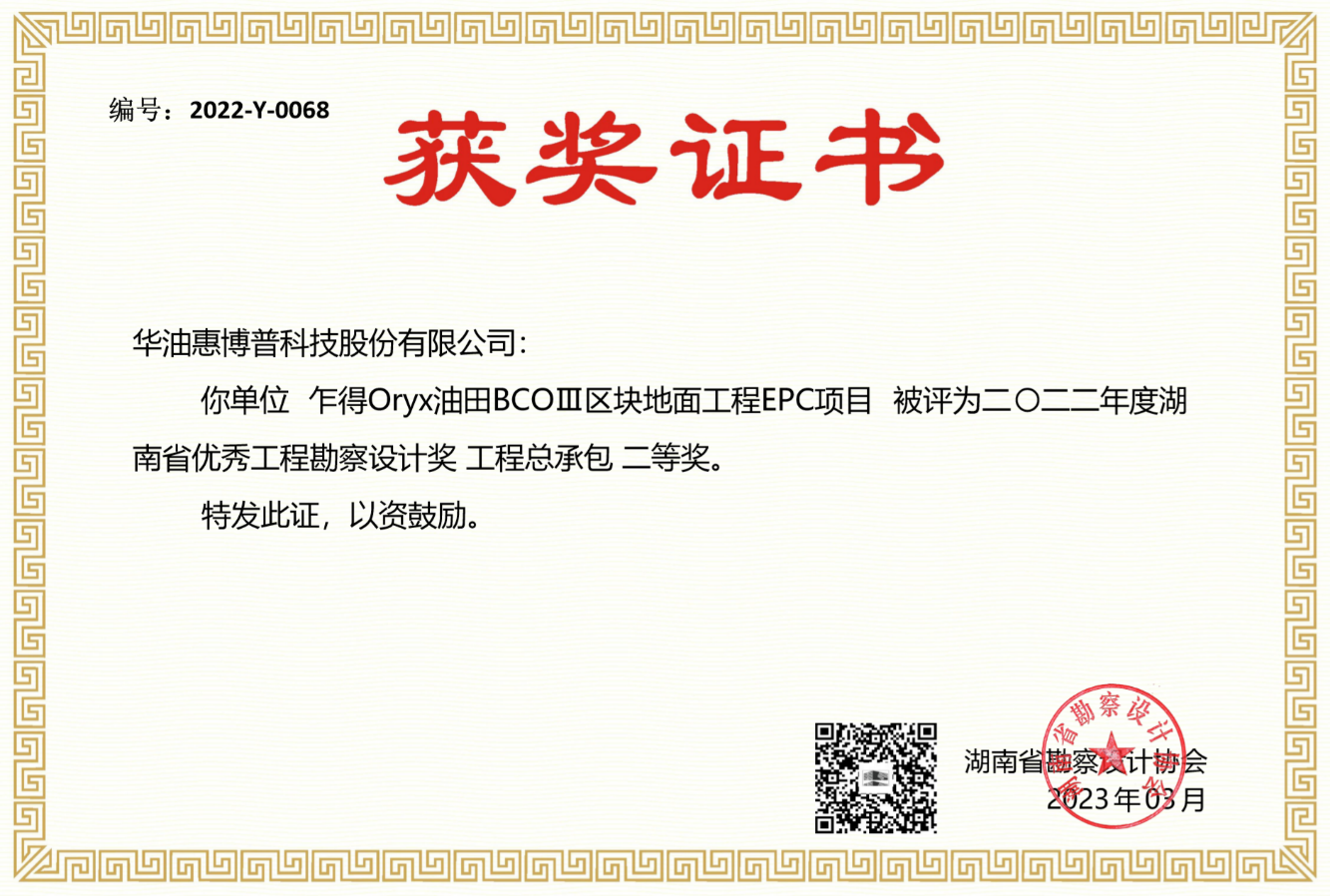

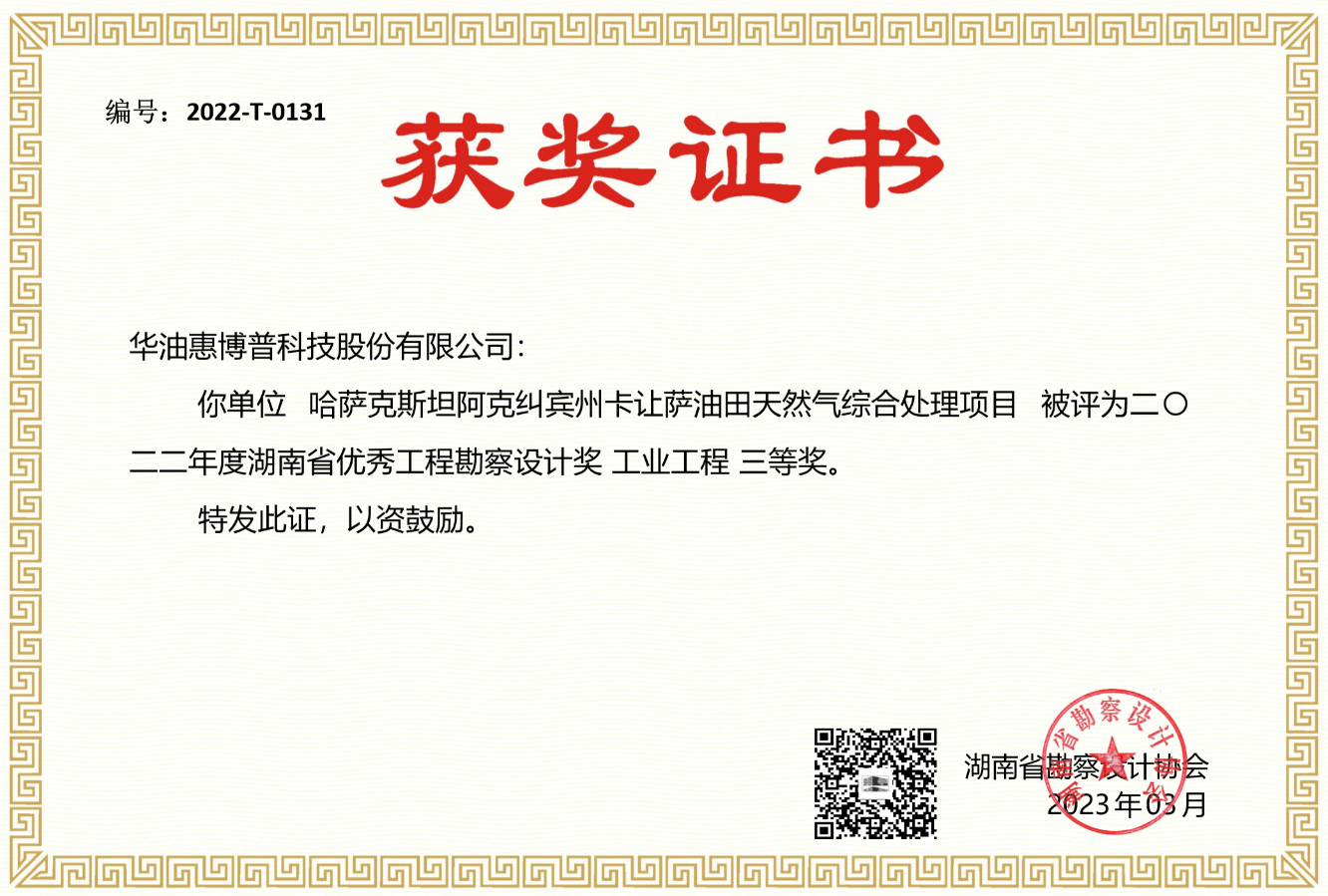

In March of the same year, projects undertaken by HBP group, namely the Chad Oryx Oilfield BCO III Block Surface Engineering EPC Project and the Kazakhstan Karachaganak Oilfield Comprehensive Gas Processing Project, were awarded the second and third prizes respectively, in the 2022 Hunan Province Excellent Engineering Survey and Design Awards.

The aforementioned awards are prestigious accolades within China's petroleum and chemical industry. HBP Group has consistently garnered professional recognition in this industry, with honors spanning specialized and industrial engineering design fields. These accolades underscore HBP Group's excellence in design innovation and comprehensive technical capabilities, symbolizing the company's survey and design proficiency on a national scale. Seizing this opportunity, the company aims to further enhance its professional technical prowess, elevate design service standards, and contribute superior design outcomes to the overarching development of the high-quality petroleum industry. This endeavor not only showcases the technological strength and proficiency of China's industrial sector, but also highlights HBP Group's commitment to maintaining a leading position in survey and design capabilities.

Chad Oryx Oilfield BCO III Block Surface Engineering EPC Project

Award: Second Prize in the 2022 Hunan Province Excellent Engineering Survey and Design Awards for Engineering General Contracting

Project Location: Southern Chad

Project Scale: This project involves the development of an integrated oilfield with an annual crude oil processing and export capacity of 500,000 tons, associated gas production of 30,000 cubic meters per day, sewage treatment capacity of 3,000 cubic meters per day, and water injection capacity of 3,360 cubic meters per day.

Project Overview: The Chad Oryx Oilfield BCO III Block development includes wellhead facilities and single well pipelines, mixed transportation and gathering pipelines, Three-Phase Pump Stations (TPPS), and Central Processing Stations (CPF). As the general contractor, HBP Group is responsible for the project's quality, safety, environmental protection, and progress. Following the rapid commissioning of the Oryx Oilfield project, it has brought significant economic benefits to the Chad government. The company actively fulfills its local and social responsibilities, showcasing a positive corporate image and establishing a strong brand presence with the owner and in the oil region, contributing to favorable social outcomes for Chinese enterprises in the local context.

Third Prize in the 2022 Hunan Province Excellent Engineering Survey and Design Awards for Industrial Engineering Design

Kazakhstan Karachaganak Oilfield Comprehensive Gas Processing Project

Awards: Third Prize in the 2023 China Petroleum and Chemical Industry Excellent Engineering Survey and Design Awards Third Prize in the 2022 Hunan Province Excellent Engineering Survey and Design Awards for Industrial Engineering Design

Project Location: Atyrau Region, Kazakhstan

Project Scale: Approximately 0.3 billion cubic meters per year of raw gas

Project Overview: This project adopts advanced amine desulfurization, molecular sieve dehydration, light hydrocarbon recovery, and sulfur recovery processes to perform gas-liquid separation on the raw gas. After compression, the gas enters the amine desulfurization unit to remove H2S and RSH. The purified gas from the desulfurization unit undergoes dehydration in the molecular sieve unit, eliminating remaining RSH, and then enters the light hydrocarbon recovery unit to produce qualified commercial gas, liquefied petroleum gas, and stable condensate oil. Commercial natural gas is exported, while liquefied petroleum gas and stable condensate oil enter the storage and loading system. The acid gas rich in H2S produced by the desulfurization unit enters the sulfur recovery system, producing sulfur particles stored in the sulfur warehouse. This facility significantly reduces the venting and burning of natural gas, achieving energy savings, environmental protection, and creating economic benefits. The comprehensive benefits highlight its significant strategic importance, demonstrating a substantial demonstrative effect in promoting integrated treatment technology for acidic gases.

In the future, HBP Group will continue to adhere to the principles of "Quality First, Customer-Centric." By providing high-quality services, the company aims to win customer satisfaction and trust. HBP Group is confident that, in the future, it will leverage its industry-leading advantages to create greater value for customers and contribute to the sustained development of the engineering survey and design industry through continuous efforts.

Copyright©2014-2023 All Rights Reserved HBP 湘ICP备2023031736号-1 Website construction: Beijing Fractal Technology Co. Ltd.